ENGINEERING & MANUFACTURING

Solutions that drive knowledge democratization and support decision intelligence

Use cases

metaphactory helps you unlock the value of your data and drive digital transformation in Industry 4.0 use cases by enabling citizen access to consumable knowledge and decision support

Challenges

in mastering the complexity of data

Solutions

that empower end users

Customized views on your data for diverse user groups

Product managers

Engineers

Service engineers

Line operators

Support engineers

Technical planners

Technical writers

metaphactory in action in engineering & manufacturing

Success stories

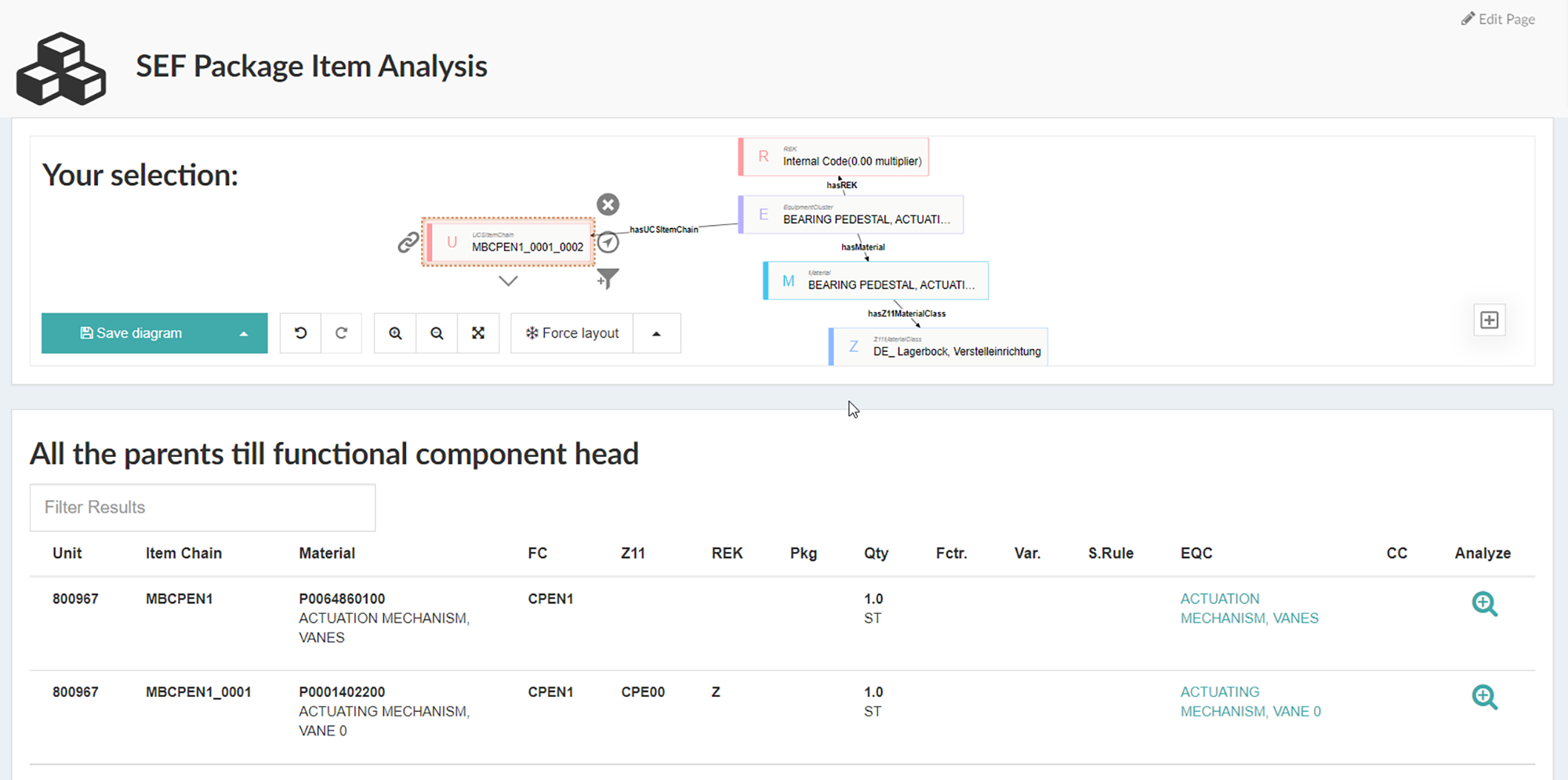

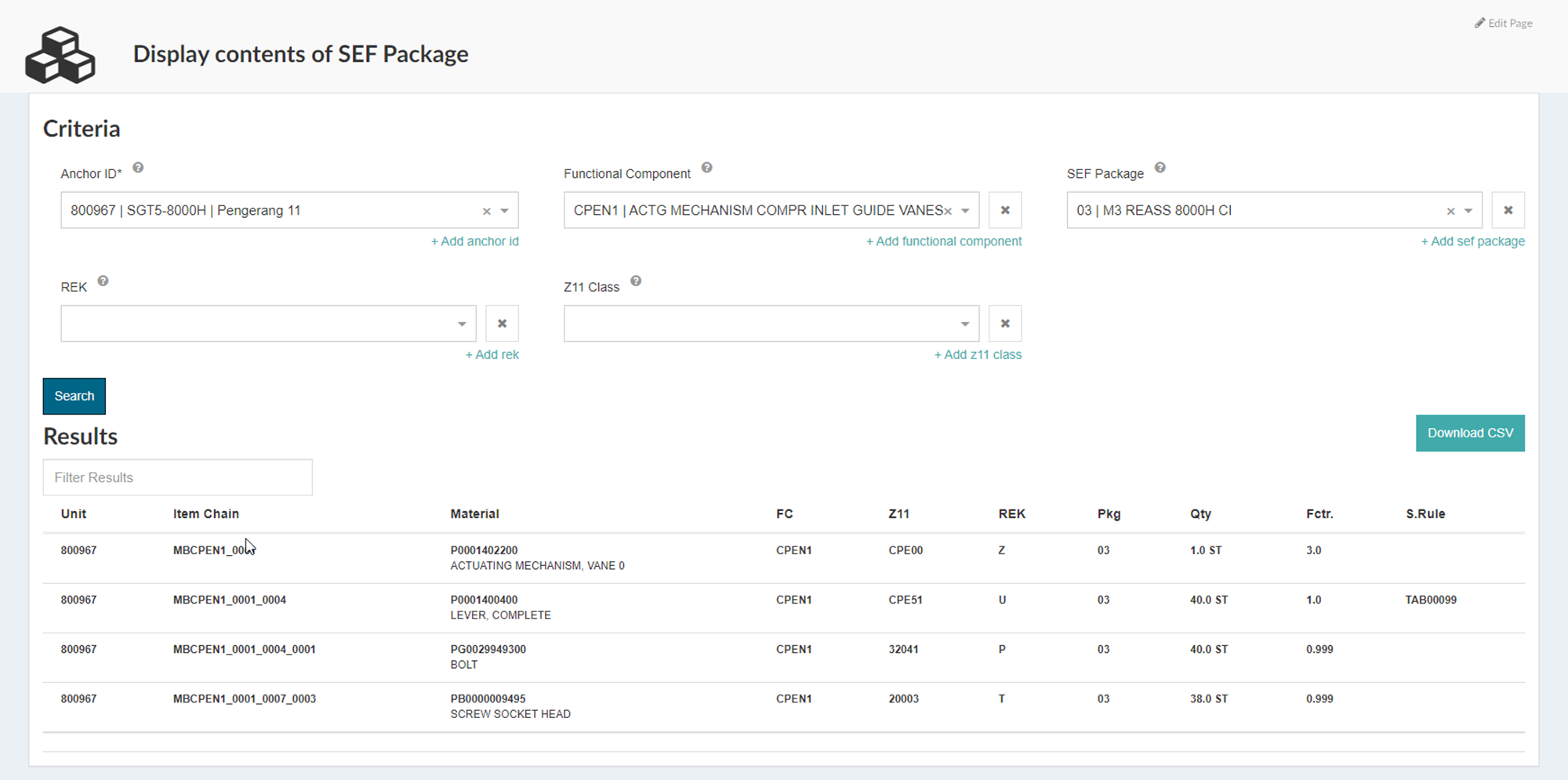

Smart turbine spare parts management at Siemens Energy

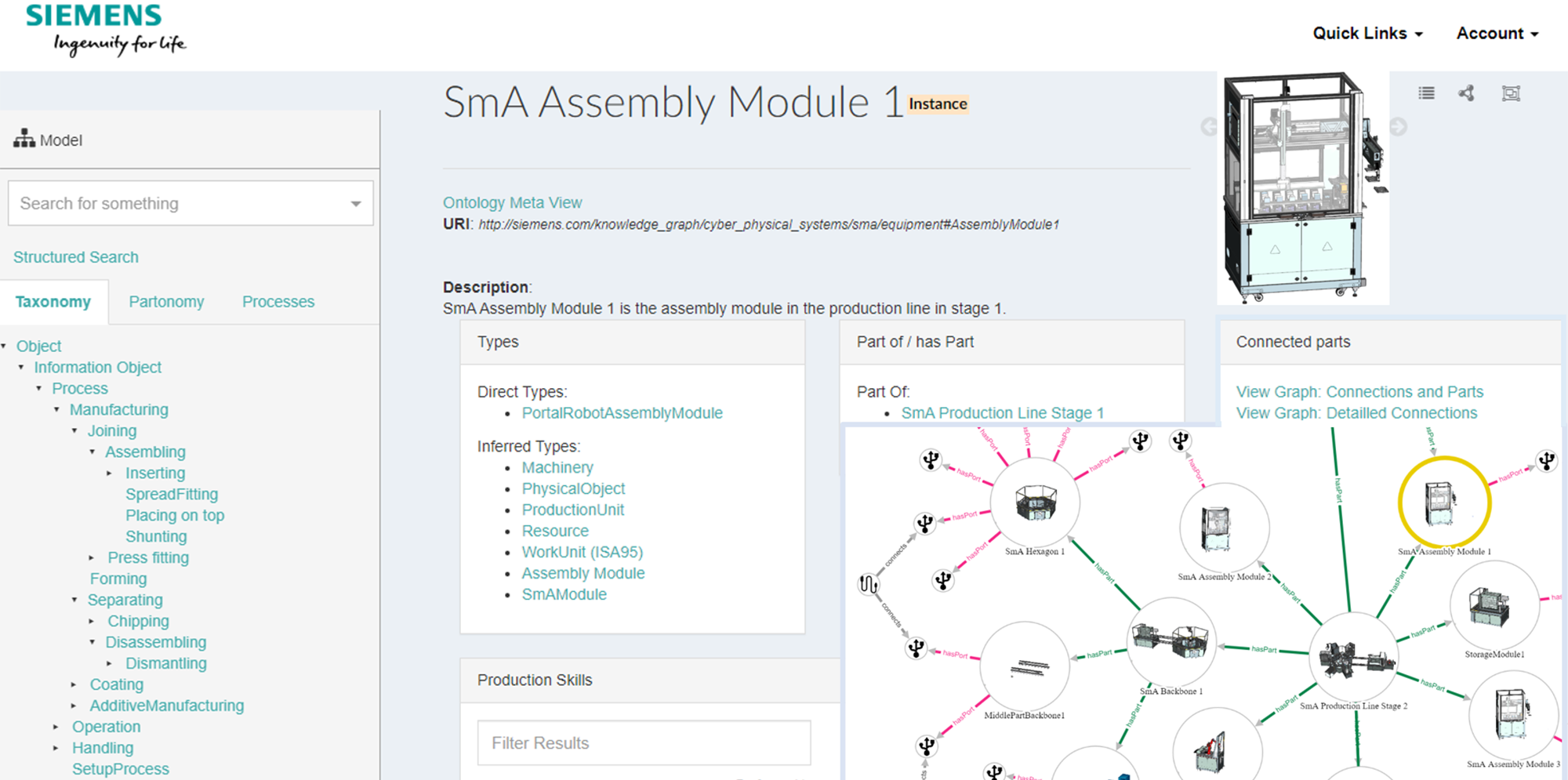

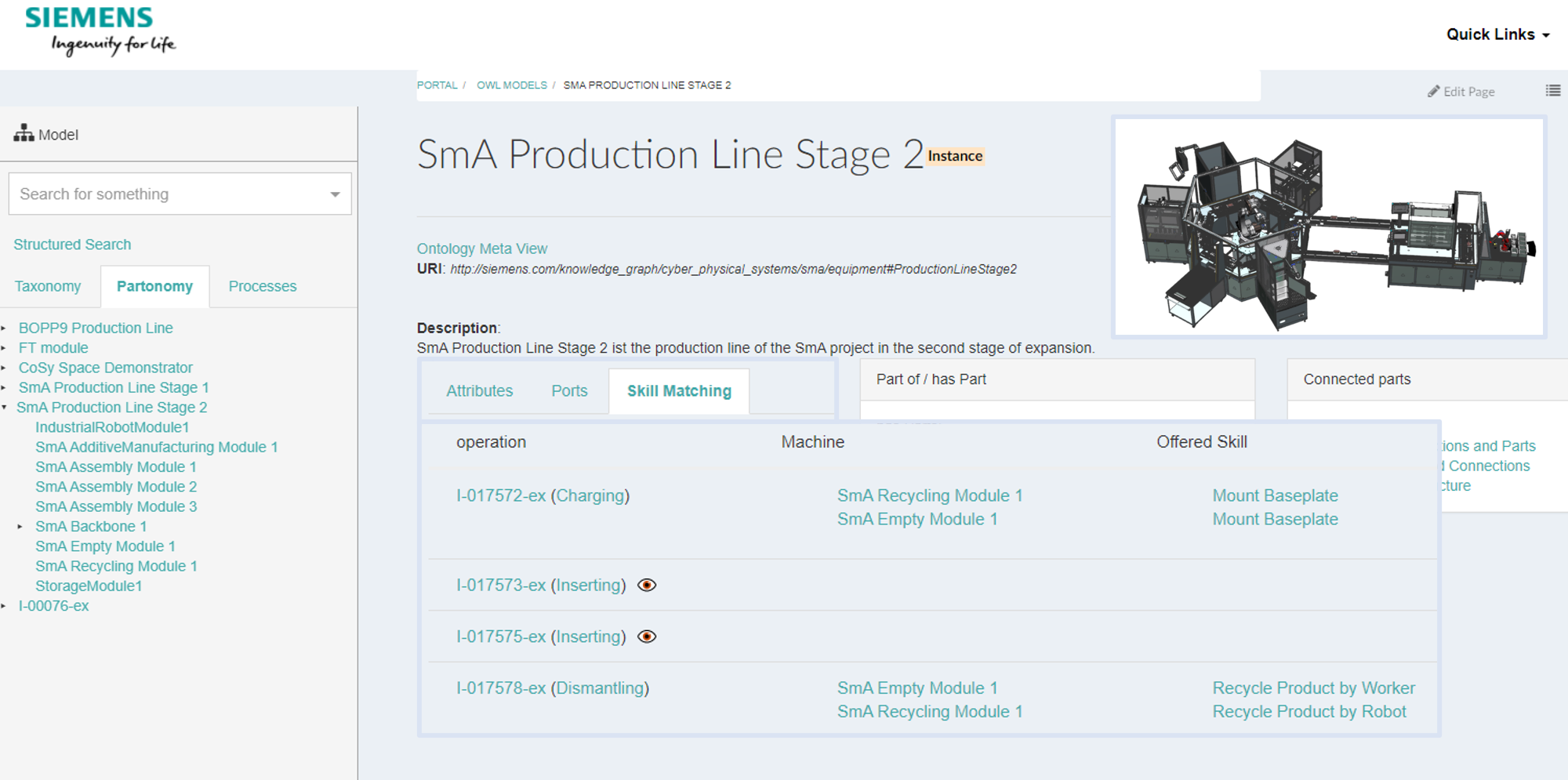

Smart manufacturing planning & execution at Siemens

Materials Science Knowledge Graph at Bosch

How does it work?

Create

Knowledge Graphs with business users

metaphactory commoditizes Knowledge Graphs, making the technology and its benefits accessible not only to knowledge graph experts but also to business users and domain experts. It supports the process of making data FAIR (Findable, Accessible, Interoperable, Reusable) and enables a cross-departmental Knowledge Graph creation process where all relevant stakeholders can:

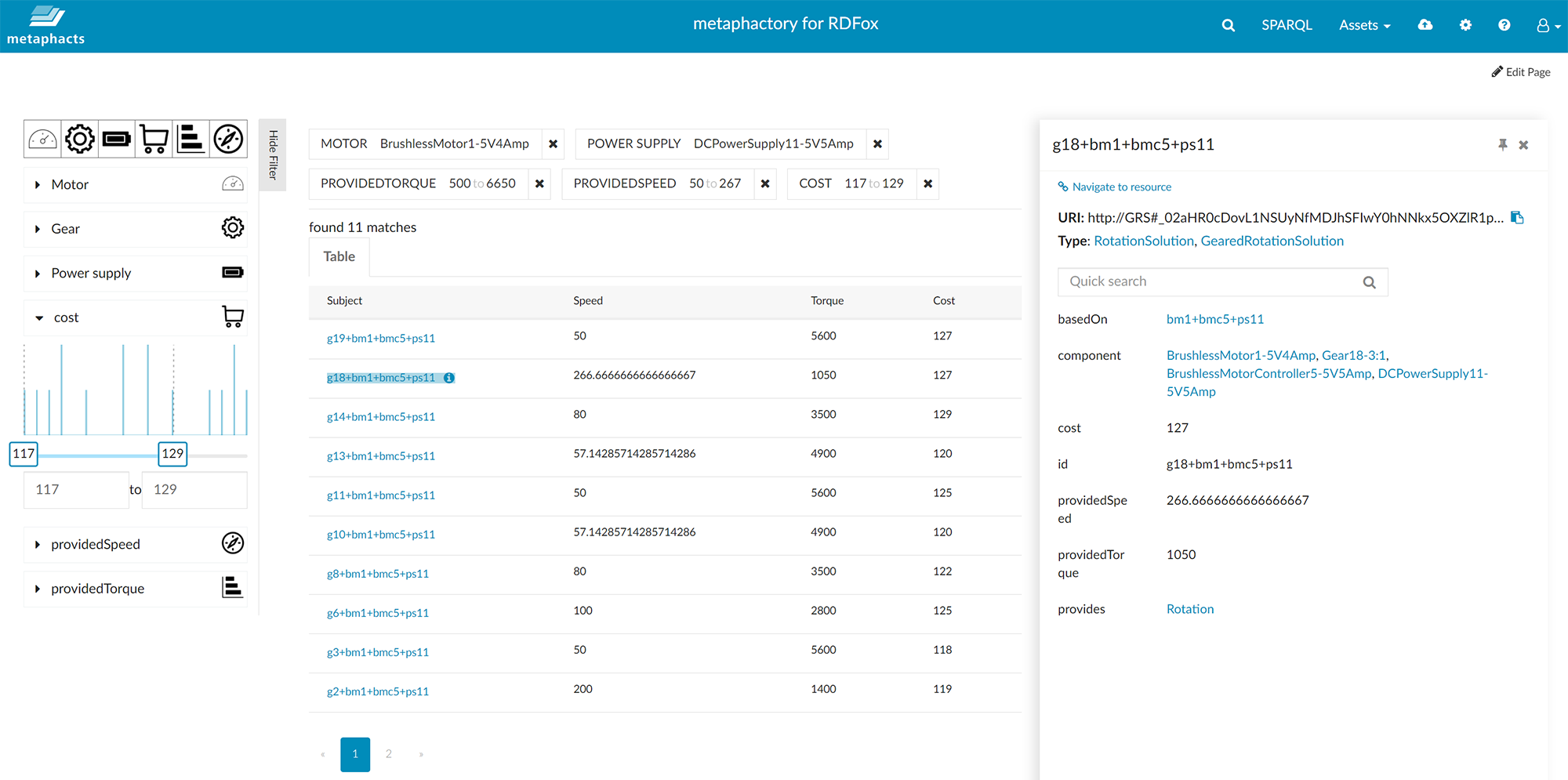

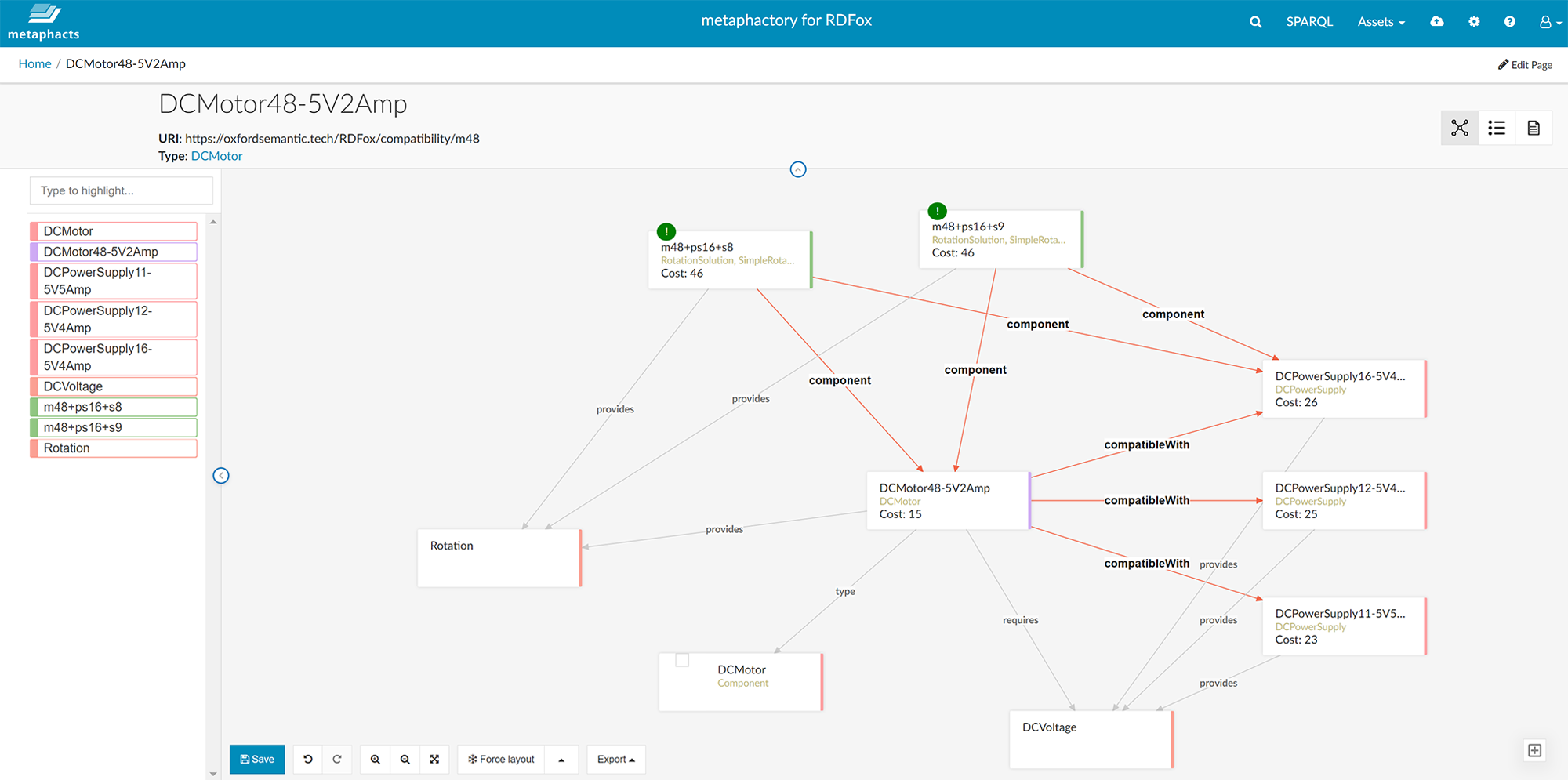

- Model core domain concepts (e.g., motors, gears, switches, power supplies and controllers, etc.) and relations based on specific business needs and in a machine- and human-interpretable format

- Map existing internal and publicly available data to the domain model

- Describe data sources and document provenance and lineage to build data reliability

Build

Knowledge Graph apps rapidly

Through its low-code approach built on a model-driven template mechanism and a rich set of ready-made Web components, metaphactory allows you to quickly build an intuitive user experience on top of your Knowledge Graph to:

- Search, filter and drill down

- Discover, visualize and explore relations

- Build insightful dashboards

- Share results with colleagues

- Add and edit data

As things change, metaphactory allows you to add new datasets, new business-oriented data definitions and new concepts to support new data domains, new user groups and new projects.